Acrylic, a versatile and aesthetically pleasing material, has become a staple in various industries, from design and architecture to manufacturing and signage. The process of shaping and crafting acrylic involves precision and expertise, and this is where acrylic machining comes into play. Delve into the intricate world of acrylic machining and the vital role played by acrylic fabrication company in bringing our creative visions to life.

I. Understanding Acrylic Machining

1. Acrylic 101: An Overview of the Material

Before delving into the intricacies of acrylic machining, it’s essential to understand the material itself. Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic known for its optical clarity, high impact resistance, and UV stability. These characteristics make it a preferred choice for various applications, ranging from display cases to medical devices.

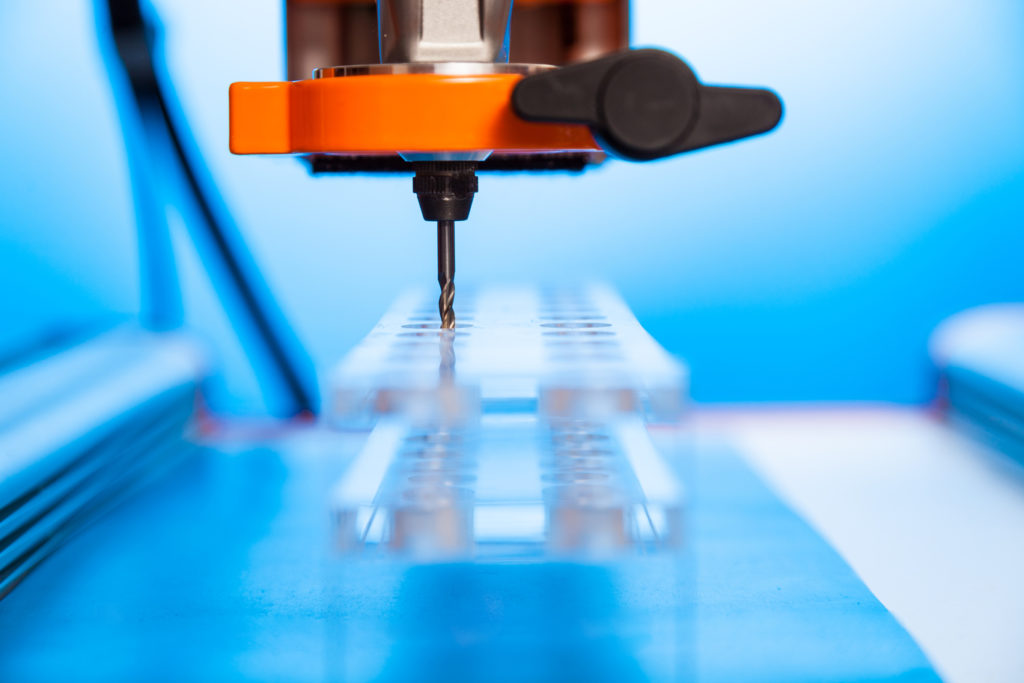

2. The Machining Process: Precision in Action

Acrylic machining involves cutting, milling, drilling, and shaping the material to achieve specific designs and dimensions. CNC (Computer Numerical Control) machines are commonly employed in this process, allowing for precise and repeatable cuts. The process demands expertise and a deep understanding of the material’s properties to prevent issues like melting or chipping.

II. The Role of Acrylic Fabrication Companies

1. Crafting Dreams: Bringing Designs to Reality

Acrylic fabrication companies play a pivotal role in turning conceptual designs into tangible products. These companies are equipped with state-of-the-art machinery and skilled artisans who understand the intricacies of working with acrylic. From creating prototypes to mass-producing components, acrylic fabrication companies bridge the gap between creativity and reality.

2. Tailored Solutions: Custom Acrylic Fabrication

One of the key strengths of acrylic fabrication companies lies in their ability to provide customized solutions. Whether it’s a unique display case for a museum, a futuristic signage project, or a medical device prototype, these companies can tailor their services to meet the specific needs of their clients. The combination of technical expertise and creativity allows for the production of one-of-a-kind acrylic pieces.

III. Challenges in Acrylic Machining

1. Precision Challenges: Overcoming Material Properties

While acrylic offers a myriad of benefits, it also presents challenges during the machining process. Its sensitivity to heat requires careful consideration, as excessive heat can lead to melting and surface imperfections.

2. Finishing Touch: Polishing and Edges

Achieving a polished finish on acrylic surfaces is crucial for enhancing its visual appeal. Acrylic fabrication companies employ various methods, such as flame polishing and diamond edge polishing, to achieve smooth and glossy surfaces. The precision in finishing touches distinguishes a professionally crafted acrylic piece from a standard product.

IV. Innovations in Acrylic Machining

1. Advanced Machinery: The Role of CNC Technology

The advent of CNC technology has revolutionized acrylic machining. CNC machines provide unparalleled accuracy and efficiency in cutting and shaping acrylic. These machines are programmed to execute intricate designs with minimal margin for error, making them indispensable in the world of acrylic fabrication. The integration of CNC technology has not only improved precision but has also accelerated the production process, enabling acrylic fabrication companies to meet tight deadlines.

2. 3D Printing in Acrylic Fabrication

The realm of acrylic machining has expanded further with the integration of 3D printing technology. While traditional machining methods involve subtractive processes, 3D printing allows for additive manufacturing, creating intricate and complex acrylic structures layer by layer. This innovation opens new avenues for creativity and enables the production of geometrically intricate designs that were once challenging to achieve through traditional methods.

V. The Future of Acrylic Fabrication Companies

1. Sustainable Practices: Eco-Friendly Acrylic Machining

As environmental consciousness grows, acrylic fabrication companies are exploring sustainable practices in their processes. This includes the use of recycled acrylic, environmentally friendly solvents, and energy-efficient machinery. By adopting eco-friendly measures, these companies contribute to reducing their environmental footprint while meeting the demands of a conscientious market.

2. Digital Integration: Virtual Prototyping and Design

The integration of digital tools in acrylic fabrication is another avenue shaping the future of the industry. Virtual prototyping and design software allows for more efficient collaboration between designers and fabricators. This digital integration streamlines the design process, reduces errors, and facilitates better communication throughout the production chain.

VI. Exploring Applications: Where Acrylic Shines

1. Design and Architecture: Creating Visual Masterpieces

Acrylic’s transparency and ability to mimic the clarity of glass make it a favored choice in design and architecture. Acrylic fabrication companies collaborate with architects and designers to produce stunning installations, structural components, and decorative elements. From modern facades to futuristic interior designs, acrylic’s versatility allows for the realization of imaginative and ambitious architectural projects.

2. Retail Displays: Capturing Attention in Stores

In the retail sector, the visual appeal of products is paramount. Acrylic proves to be an ideal material for crafting attention-grabbing displays. Acrylic fabrication companies design and produce display cases, shelves, and signage that not only showcase products effectively but also contribute to the overall aesthetic of retail space. The material’s ability to transmit light further enhances its suitability for creating dynamic and eye-catching displays.

Get to know about KPong KRNL Key and enhance your gaming experience.

3. Medical Applications: Precision in Healthcare

The medical industry benefits from acrylic’s unique combination of properties. Acrylic fabrication companies play a crucial role in manufacturing components for medical devices, laboratory equipment, and protective barriers. The precision required in these applications demands expertise in acrylic machining to ensure the production of sterile and durable components that meet stringent industry standards.

VII. The Artisans Behind the Scenes: Skilled Craftsmanship

1. Precision Machinists: Masters of Acrylic Shaping

Acrylic fabrication companies are home to skilled machinists who are adept at transforming raw acrylic sheets into intricate and precise components. These artisans possess a deep understanding of the material’s behavior and utilize their expertise to navigate the challenges associated with acrylic machining. Their craftsmanship ensures that the final products meet the highest standards of quality and aesthetics.

2. Design Engineers: Merging Creativity with Functionality

Collaboration between designers and engineers is a hallmark of successful acrylic fabrication companies. Design engineers work closely with clients to understand their vision and translate it into feasible and functional designs. This collaborative approach ensures that the final product not only meets aesthetic expectations but also adheres to practical considerations, such as structural integrity and usability.

3. Finishing Experts: Perfecting the Look and Feel

The journey from a raw acrylic sheet to a finished product involves meticulous attention to detail during the finishing stages. Finishing experts in acrylic fabrication companies specialize in techniques such as polishing, beveling, and flame polishing to achieve the desired look and feel. Their expertise adds the final touch to the product, elevating its visual appeal and ensuring it meets the client’s specifications.

Conclusion

In the world of design, architecture, and manufacturing, acrylic has emerged as a preferred material for its aesthetic appeal and versatility. Acrylic machining, facilitated by acrylic fabrication companies, transforms creative visions into tangible reality. With advancements in technology, the future promises even more innovative approaches, from sustainable practices to digital integration. As acrylic fabrication companies continue to evolve, they stand at the forefront of turning acrylic into not just a material but a medium through which imagination takes form.