PAT Test Certificate, in the context of making sure that workplace safety is maintained and in compliance with the law Two terms that frequently come up include “Electrical safety Testing” as well as “PAT Testing.” While both are vital aspects of ensuring an environment that is safe for workers however, they differ in their techniques, scopes and methods. In this thorough guide, we examine the subtleties that separate these two procedures from one another, and aim to give an knowledge of their functions and their applications, PAT Test Certificate

What exactly is Electrical Safety Testing?

Safety Testing for Electrical Safety Testing is a comprehensive test of electrical devices and systems to make sure they are in compliance with safety standards. The testing isn’t limited to a particular type of equipment, but it covers a broad range which includes machines, appliances or power distribution system. The goal is to determine the potential electrical dangers like earth continuity, insulation resistance and the polarity.

| Aspect | Definition |

| Objective | To assess electrical equipment and systems to ensure compliance with safety standards and identify potential hazards. |

| Scope | Encompasses a wide range of electrical systems, including appliances, machinery, and power distribution systems. |

| Testing Methods | Involves various methods such as insulation resistance testing, earth continuity testing, and polarity testing. |

| Frequency of Testing | Conducted at regular intervals based on factors like the type of equipment, usage, and the operating environment. |

| Applicability | Applicable to diverse electrical equipment, from complex industrial machinery to basic office appliances. |

| Legal Compliance | Often required to comply with legal regulations and standards ensuring workplace safety and adherence to electrical safety norms. |

| Benefits | Enhances overall workplace safety, helps prevent electrical malfunctions, reduces the risk of fire, and ensures compliance with safety regulations |

The significance of PAT testing

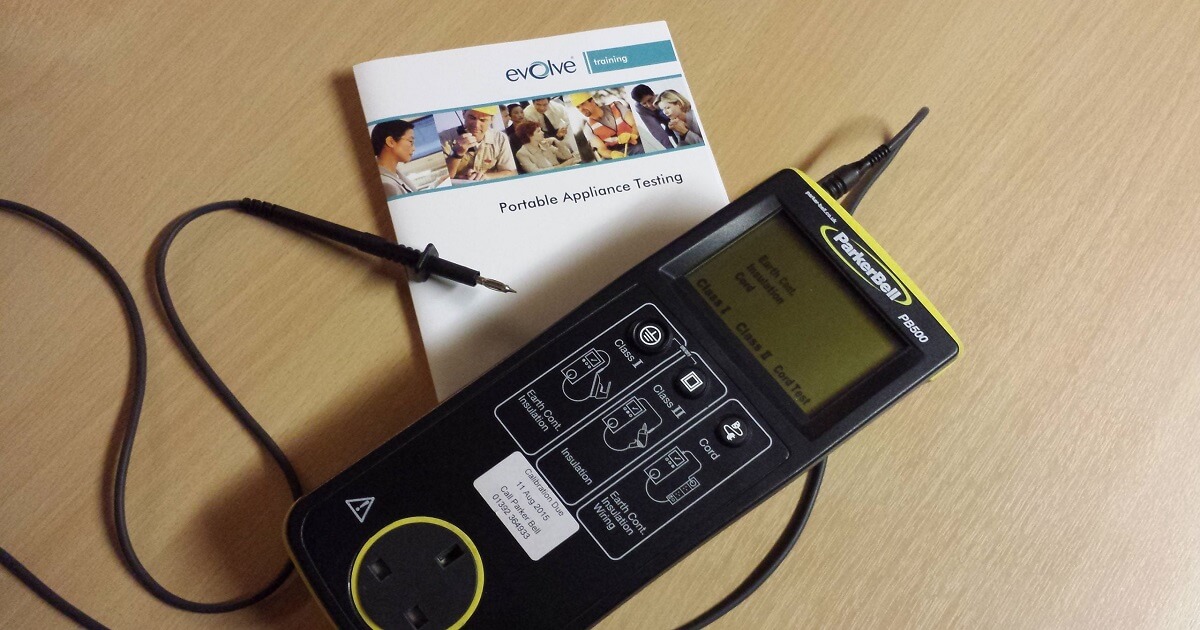

Portable Appliance Testing, commonly called PAT Testing, is a subset of electrical safety tests. It is focused on electrical appliances that are portable testing their safety for use. This could include anything from office equipment such as printers and computers, to kitchen appliances and power tools. PAT Testing makes sure that these equipments are not contaminated with problems that could cause danger for the user or anyone else within the area.

There are key differences between electrical Safety Testing and PAT Testing

Scope and purpose

The primary distinction is in the nature and intent the tests are conducted. Safety Testing for Electrical Safety Testing encompasses a broader scope, testing all electrical equipment and systems to ensure that they are in compliance with safety standards. However, PAT Testing is more focused on portable devices to determine their safety in different situations.

Methods for Testing

Safety Testing for Electrical Safety Testing involves a variety of methods, which include resistance testing for insulation and earth continuity testing and testing for polarity. These tests evaluate various aspects of electrical devices to ensure their safety overall. PAT Testing, while using some of these techniques is more focused on inspections of the visual of earth continuity, earth continuity, and testing the resistance of insulation on portable appliances.

Frequency of testing

Testing frequency can vary in both. Electric Safety Testing usually performed at regular intervals, based on the kind of equipment as well as the environment that it operates in. Contrarily, PAT Testing may have periodic testing schedules particularly for equipment operating in hazardous or demanding environments.

Application

Electrical Safety Testing can be applied to a wide range of electrical equipment and systems including complex industrial machinery to the simplest office equipment. PAT Testing however, is designed specifically to be portable, with a focus on the ones that are used in settings that require mobility as a major element.

Legal Compliance

Both tests are needed to ensure compliance with the laws and regulations. Electrical Safety Testing ensures that an establishment is compliant with the overall safety requirements for electrical equipment, while PAT Testing is, in a variety of states, is a legal requirement to ensure the safety of workers and compliance with electrical appliance standards.

The benefits in Electrical Safety Testing

- It identifies the potential hazards within the vast array types of electronic equipment.

- Increases overall safety in the workplace.

- Aids in preventing electrical problems and decreases the possibility of fire.

- Make sure that the safety regulations are in compliance and standards.

The benefits of testing PAT

- A particular focus is placed on portable devices essential for workplaces with a variety of jobs.

- Discovers defects in portable appliances which may not be noticed during the normal usage.

- Reduces the danger of electrical shocks or fire caused by malfunctioning portable appliances. It reduces the risk of electric shock or fire caused by faulty portable.

- Represents a commitment to safety that can increase confidence in employees.

Common Questions and Answers on electrical Safety Testing and PAT Testing

Do you think PAT Testing is required?

In many countries PAT Testing is a requirement in many countries particularly in workplaces in which portable appliances are widely utilized. It is an obligation of law to ensure the safety of employees as well as comply with electrical safety standards.

What is the frequency at which electrical safety tests be conducted?

The frequency of testing electrical safety is contingent on a variety of variables, including the kind of equipment, its use and the surrounding. In general, it is suggested to test these devices regularly, and with more frequent testing for the most critical equipment.

“Electrical Safety Testing serves as the vigilant guardian of workplace safety, ensuring that electrical equipment is scrutinized, hazards are identified, and compliance with stringent safety standards becomes an unwavering priority.”

What equipment is usually used in PAT Testing?

PAT Tests cover a vast variety of portable appliances which includes but not limited to printers, computers kitchen appliances, power extension cords, and tools. Any device that has an outlet is eligible of PAT Testing.

Does PAT Testing have to be performed at-home?

While a few basic visual inspections are possible on-site, the complete PAT Testing process usually requires special equipment and experience. Many companies choose to employ professionals to ensure complete and accurate assessment.

What do you get if you don’t conduct the electrical safety test?

Failure to conduct electrical safety tests can cause a myriad of consequences, including an increase in the risks of electrical risks, the possibility of fires, and not complying with the law. This can result in massive financial losses due to equipment failure or reduction in productivity.

Conclusion

In conclusion, although Electrical Safety Testing and pat testing near me have the same objective of ensuring safety in electrical installations however, they differ in terms of scope, methodology and application. Understanding the differences is crucial for both individuals and businesses in the creation of comprehensive safety plans. It doesn’t matter if it’s the comprehensive assessment of electrical systems, or the specific inspection of portable appliances making sure safety is a priority through these testing methods is a way to invest in the wellbeing of individuals and the durability for electrical devices. As workplace regulations change and changes, being aware about these procedures is essential for ensuring a safe and safe working environment.