In the dynamic realm of plant design and engineering, precision, efficiency, and seamless collaboration are paramount. Plant Design Management System, PDMS software has emerged as a cornerstone in the field, providing engineers with a powerful toolset to navigate the complexities of designing and managing intricate industrial facilities.

This article explores the key features, benefits, and transformative impact of PDMS software in the landscape of plant design and construction.

Defining PDMS Software:

PDMS, or Plant Design Management System, is a comprehensive software solution developed by AVEVA, designed to facilitate the entire plant design and engineering process. It serves as a virtual environment where engineers can create detailed 3D models, simulate processes, and manage data across the entire lifecycle of a project.

Plant Design Management System (PDMS) is a sophisticated software solution developed by AVEVA to address the complex challenges associated with plant design and engineering. PDMS is specifically designed to facilitate the creation, management, and optimization of detailed 3D models of plant infrastructure, offering a comprehensive set of tools for professionals in the fields of architecture, engineering, and construction.

Key Features and Capabilities:

a. 3D Modeling and Visualization:

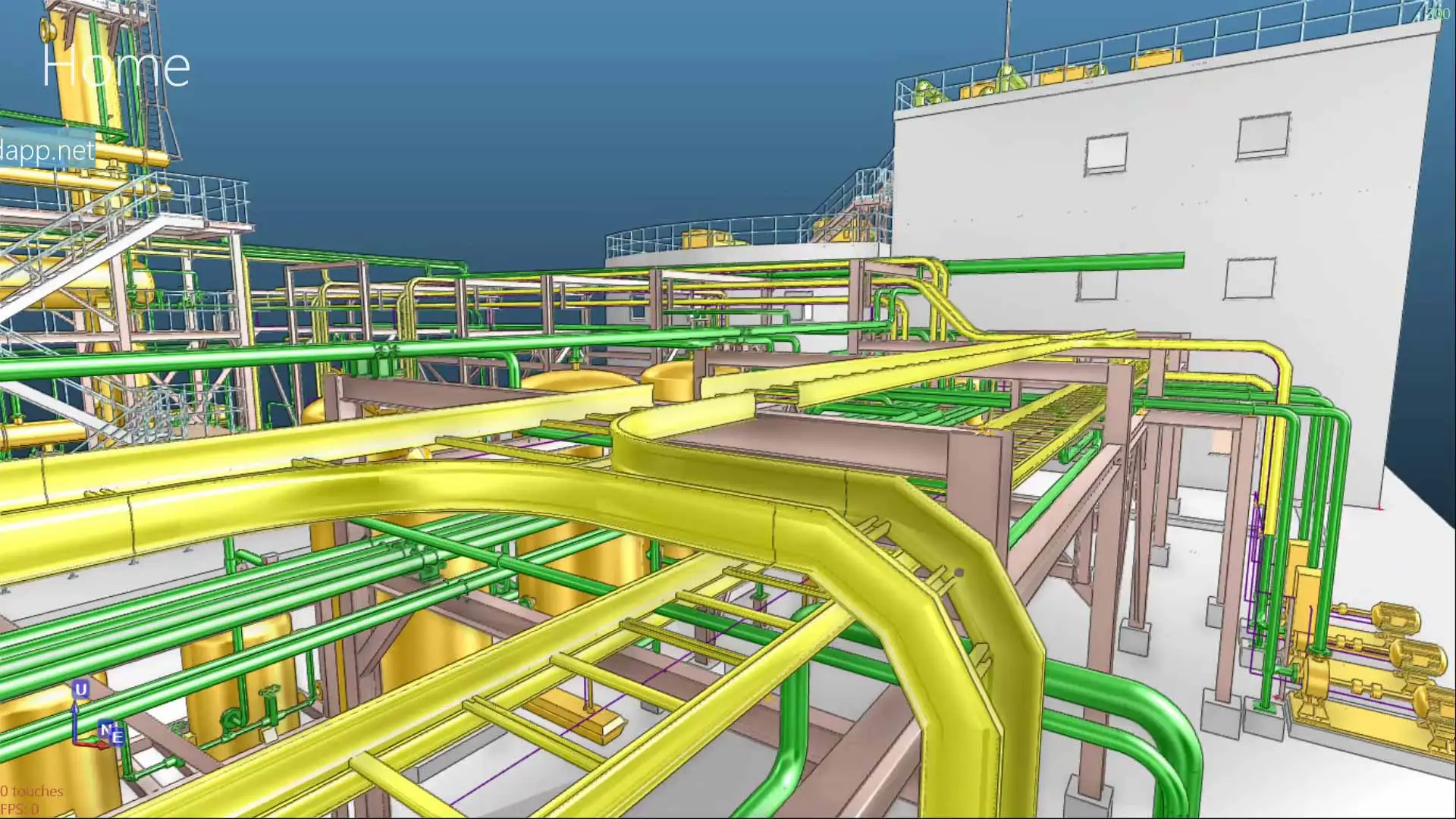

PDMS excels in creating detailed 3D models of entire plants, including structures, equipment, piping, and instrumentation. The visual representation provides a holistic view of the facility, aiding in better understanding and decision-making.

b. Integrated Design Environment:

PDMS offers an integrated environment that fosters collaboration among different engineering disciplines. Piping, electrical, instrumentation, and structural components seamlessly come together in a unified platform, enhancing coordination and communication.

c. Data Management:

The software provides robust data management capabilities, ensuring that project information is organized, accessible, and up-to-date. This includes version control, change management, and linking design data with project documentation.

d. Clash Detection and Resolution:

PDMS includes advanced clash detection tools that identify and resolve potential conflicts in the design phase. This proactive approach minimizes issues during construction, reducing rework and project delays.

A notable feature of PDMS is its powerful clash detection tools. Engineers can identify and resolve clashes or conflicts in the design phase, preventing potential issues during construction. This proactive approach contributes to the overall efficiency and success of the project.

Read more about how x*x*x is equal to 2 and get aware of it.

Materials and Specifications Management:

PDMS includes robust tools for managing materials, specifications, and standards. Engineers can efficiently select and apply materials, ensuring that the design complies with industry standards and regulatory requirements. This feature is essential for maintaining the integrity and safety of the plant infrastructure.

Comprehensive Visualization:

The software offers a comprehensive and detailed visualization of the plant design. This visual representation is not only beneficial during the design phase but also serves as a valuable tool for project reviews, stakeholder presentations, and decision-making throughout the project lifecycle.

Benefits of PDMS Software:

a. Enhanced Collaboration:

PDMS promotes collaboration among different engineering disciplines, enabling seamless communication and coordination. This collaborative environment leads to a more integrated and efficient project workflow.

b. Efficiency and Accuracy:

The 3D modeling capabilities of PDMS significantly improve the efficiency of the design process. Engineers can create accurate and detailed models, reducing the likelihood of errors and optimizing the overall design.

c. Cost Savings:

The clash detection features and improved efficiency contribute to cost savings by minimizing rework and project delays. PDMS aids in delivering projects within budget constraints while maintaining high-quality standards.

d. Visualization and Simulation:

The software’s visualization and simulation capabilities allow engineers to assess the design’s performance in a virtual environment. This ensures that the plant design meets operational requirements and identifies potential issues before construction begins.

Integration with Other AVEVA Solutions:

PDMS seamlessly integrates with other AVEVA solutions, creating a comprehensive ecosystem for plant design, operations, and maintenance. This integration ensures a smooth flow of data and information throughout the entire lifecycle of the plant.

Future Trends and Developments:

As technology continues to advance, PDMS is expected to evolve with industry trends. Integration with emerging technologies such as augmented reality (AR), virtual reality (VR), and digital twins may further enhance the software’s capabilities, offering new dimensions to plant design and engineering.

Conclusion:

PDMS software stands at the forefront of revolutionizing plant design and engineering. Its comprehensive features, collaborative environment, and efficiency improvements have positioned it as an invaluable tool for navigating the complexities of industrial projects. As industries continue to embrace digital transformation, PDMS remains a driving force in shaping the future of plant design and construction, ensuring that engineers have the tools they need to succeed in an ever-evolving landscape.