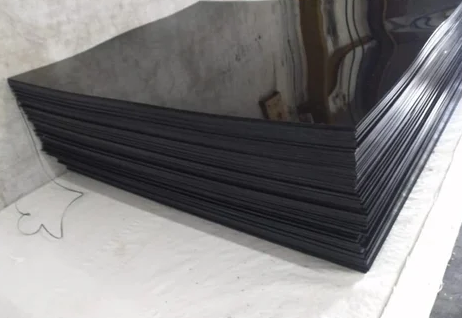

In the realm of versatile and durable materials, HDPE (High-Density Polyethylene) sheets stand as a testament to innovation and reliability. As a manufacturer dedicated to excellence, our journey unfolds in the intricate artistry of crafting HDPE sheets. This blog delves into the meticulous process, the applications, and the unwavering commitment to quality that defines our role as an HDPE sheets manufacturer.

The Art of HDPE Sheet Manufacturing

1. Precision in Polymerization

The journey begins with the polymerization of high-density polyethylene. Meticulous precision in this stage ensures the formation of a polymer with the desired molecular structure, a crucial factor influencing the strength and characteristics of the HDPE sheets.

2. Extrusion Mastery

Extrusion is the artistry that shapes raw material into sheets. Our manufacturing process leverages state-of-the-art extrusion machinery, where the polymer undergoes controlled heating, forming a continuous sheet. The extrusion process ensures uniformity and consistency in thickness—a hallmark of quality in HDPE sheet manufacturing.

The Canvas: Applications of HDPE Sheets

1. Protective Shields in Construction

HDPE sheets are the protective shields of the construction world. From weather-resistant barriers to durable roofing solutions, our manufactured HDPE sheets contribute to the structural integrity and longevity of construction projects.

2. Containers for a Sustainable Tomorrow

In the realm of packaging, HDPE sheets emerge as sustainable champions. As a manufacturer, we craft sheets that are transformed into robust containers, ensuring the safe storage and transportation of goods while minimizing environmental impact through recyclability.

Commitment to Quality: The Heart of HDPE Sheet Manufacturing

1. Rigorous Quality Control Measures

Quality is not a compromise; it’s a commitment. Our manufacturing process incorporates rigorous quality control measures at every stage. From raw material inspection to final product testing, each sheet undergoes meticulous scrutiny to meet and exceed industry standards.

2. Sustainability at the Core

As an HDPE sheets manufacturer, our commitment extends beyond product quality to environmental responsibility. We embrace sustainable practices, including the use of recycled materials and eco-friendly production processes. The result is not just sheets of high quality but sheets with a minimal ecological footprint.

Collaborative Innovation: Partnering for Progress

1. Custom Solutions for Varied Needs

We understand that each project is unique. As a manufacturer, we offer custom solutions tailored to the specific needs of our clients. Whether it’s a construction project requiring specialized barriers or packaging solutions demanding unique dimensions, our commitment is to provide tailored excellence.

2. Collaborative Research and Development

Innovation thrives in collaboration. Our R&D initiatives actively involve collaboration with clients, architects, and industry experts. By understanding evolving needs and technological advancements, we continuously refine our manufacturing processes, ensuring our HDPE sheets align with the latest standards and expectations.

Future Horizons: Charting the Path Forward

1. Integration with Emerging Technologies

The future of HDPE sheet manufacturing is entwined with emerging technologies. From smart materials with embedded sensors to innovations in polymer science, our commitment is to integrate these advancements, shaping the next generation of HDPE sheets.

2. Empowering Sustainable Practices Across Industries

As an HDPE sheets manufacturer, our vision extends to empowering sustainable practices across industries. We actively collaborate with businesses, architects, and policymakers to promote the use of HDPE sheets as a sustainable choice, contributing to a greener and more eco-conscious future.

The Intricate Dance: Advanced Techniques in HDPE Sheet Manufacturing

1. Advanced Blending for Optimal Properties

Crafting high-performance HDPE sheets requires a delicate dance of blending. Our manufacturing process incorporates advanced blending techniques, ensuring that the HDPE sheets possess optimal properties such as flexibility, impact resistance, and UV stability. This meticulous blending is a key contributor to the sheets’ exceptional durability.

2. Precision in Thickness Control

A symphony demands precision, and so does the manufacturing of HDPE sheets. Our process includes cutting-edge thickness control mechanisms, ensuring that each sheet meets exact specifications. This precision is crucial, especially in applications where uniform thickness is paramount, such as construction and industrial usage.

The Canvas Expands: Exploring Niche Applications

1. Architectural Innovation with Textured HDPE Surfaces

As manufacturers, we go beyond the conventional. Textured HDPE surfaces emerge as an innovation, finding applications in architectural design. From artistic façades to aesthetically pleasing cladding, textured HDPE sheets add a layer of creativity to construction projects, showcasing the versatility of our manufacturing capabilities.

2. HDPE Sheets in Art Installations

The canvas of HDPE extends to art installations. As a manufacturer, we take pride in providing sheets that artists transform into captivating sculptures and installations. The lightweight yet sturdy nature of HDPE sheets allows artists to push the boundaries of creativity, illustrating the diverse and artistic applications of our manufactured sheets.

Quality Redefined: Innovations in HDPE Sheet Manufacturing

1. Enhanced Resilience with UV Stabilization

Understanding the environmental challenges, our commitment to quality includes innovations like UV stabilization. This feature enhances the resilience of HDPE sheets against prolonged exposure to sunlight, making them ideal for outdoor applications where UV resistance is crucial.

2. Fire-Resistant Formulations for Safety

In environments where fire safety is paramount, our manufacturing process incorporates fire-resistant formulations. These specialized HDPE sheets provide an additional layer of safety, making them suitable for applications where fire resistance is a critical requirement.

Sustainable Futures: HDPE Sheets in the Green Movement

1. Closed-Loop Recycling Initiatives

Our commitment to sustainability takes center stage through closed-loop recycling initiatives. By actively engaging in the recycling process, we contribute to the circular economy. Recycled materials are seamlessly integrated into our manufacturing process, reducing waste and minimizing the environmental impact of HDPE sheet production.

2. Eco-Friendly Packaging Solutions

In response to the global call for eco-friendly practices, our manufacturing extends to the production of HDPE sheets for sustainable packaging solutions. These sheets provide businesses with an environmentally responsible choice, aligning with the growing demand for green alternatives in packaging.

Collaborative Excellence: Partnering for Future Achievements

1. Collaborative Projects with Architects and Designers

Our commitment to excellence extends to collaborative projects with architects and designers. By engaging in joint ventures, we explore the uncharted territories of HDPE applications. From futuristic architectural designs to avant-garde installations, these collaborations push the boundaries of what HDPE sheets can achieve.

2. Tailoring Solutions for Industry-Specific Needs

Recognizing the diversity of industry needs, our manufacturing ethos includes tailoring solutions for specific sectors. Whether it’s providing specialized HDPE sheets for the automotive industry or creating solutions for the agricultural sector, our manufacturing prowess aligns with the unique demands of each industry.

Final Crescendo: HDPE Sheets, a Symphony of Possibilities

In conclusion, the manufacturing of HDPE sheets is a symphony, where precision, innovation, and sustainability harmonize. From advanced techniques to niche applications, from redefined quality standards to contributions to the green movement, HDPE sheets crafted with excellence are a testament to the limitless possibilities they offer.